Mining Equipment Inspections

Ensuring Uptime Through Condition Monitoring

In the demanding mining industry, maintaining uptime and ensuring safety are critical. From identifying equipment issues early to safeguarding mining sites, advanced technologies like thermal imaging and acoustic imaging allow mining companies to catch problems in their early stages—before equipment is compromised or destroyed and before costly accidents happen.

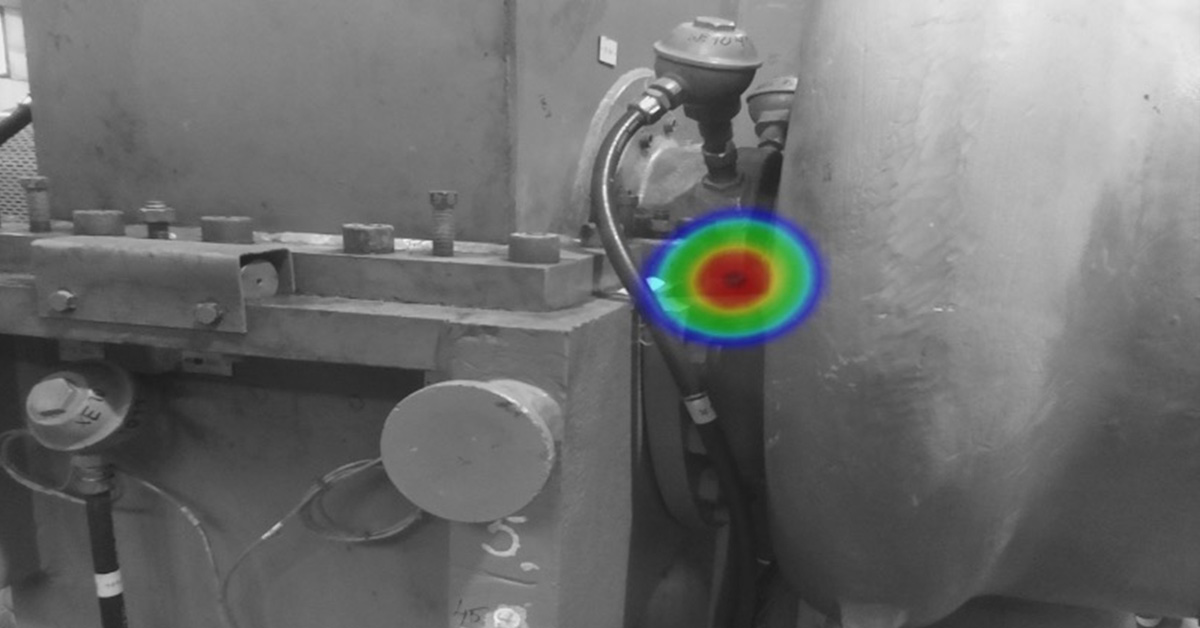

Real-Time Liquid Leak Detection

Mining processes often involve the use of hazardous and expensive chemicals. Locating small liquid leaks across large mining sites can be challenging with traditional methods.

- Thermal imaging cameras quickly identify temperature differences, allowing operators to pinpoint leaks within seconds.

- Acoustic imaging cameras detect sound anomalies associated with leaks, even in noisy environments, offering an additional layer of detection.

Prevent Equipment Failures and Improve Workplace Safety

Mining equipment such as tires, pipes, and conveyors is prone to wear and tear. Regular inspections are essential to ensure reliability and safety.

- Thermal imaging highlights temperature variations, identifying overheating components or potential failures.

- Acoustic imaging detects irregular sound patterns, such as those caused by failing bearings or misaligned machinery, enabling early intervention.

Combat Illegal Mining with Advanced Security

Thermal imaging improves mining security by offering 24-hour surveillance of properties. Infrared images identify intruders quicker and with far greater accuracy than other security methods.

FLIR's Solutions for Mining

Acoustic Imaging: Enhancing Conditiong Monitoring Alongside Thermal Imaging

Thermal imaging is a powerful tool for detecting temperature-related anomalies, and acoustic imaging for mining complements it by focusing on sound. By converting sound waves into visual data, acoustic imaging adds another dimension to condition monitoring, offering insights that work in harmony with thermal imaging.

- Gas Leak Detection: Acoustic imaging cameras can identify leaks in pressurized pipelines by visualizing sound anomalies.

- Electrical Fault Detection: Detect issues like arcing or corona discharge in high-voltage systems.

- Mechanical Fault Monitoring: Pinpoint issues such as abnormal vibrations or bearing failures in rotating machinery.

Integrating acoustic and thermal imaging gives mining operators a more complete picture of their equipment’s health, helping to prevent failures and reduce downtime.

Mining Operations: How Acoustic Imaging Cameras Help Detect Compressed Air Leaks 🡆

Acoustic imaging camera detecting a compressed air leak

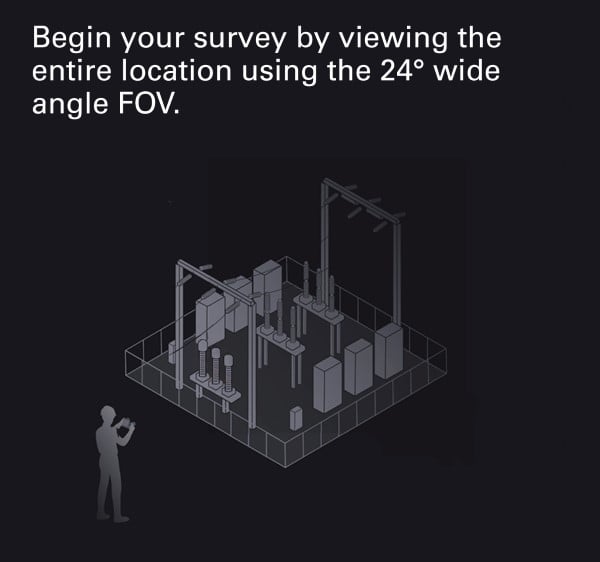

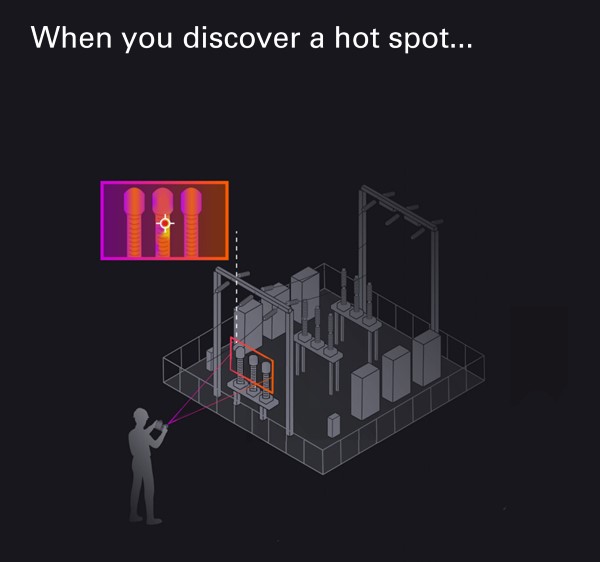

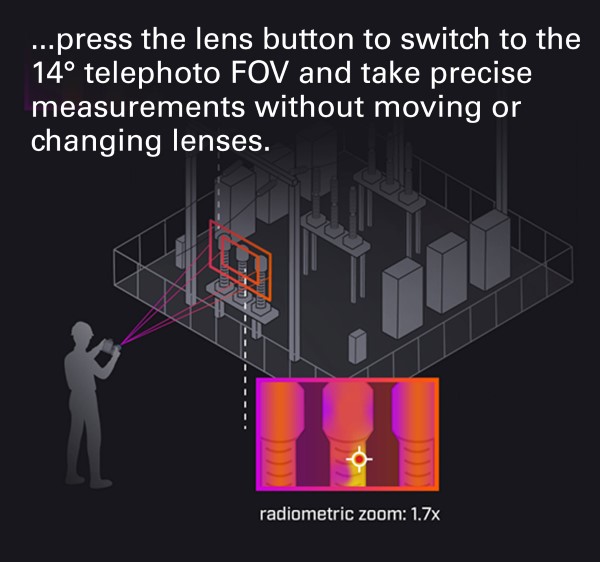

The FLIR FlexView™ Lens

Designed to improve operational efficiency, the FLIR FlexView™ lens allows for quick and accurate image capture during inspections. With the push of a button, FLIR FlexView dual field of view (DFOV) lenses let you switch between wide and narrow lenses in a second. Use wide-field for tight spaces and target context and switch to narrow to put more pixels on target.

Whether inspecting machinery, monitoring leaks, or enhancing safety, FlexView ensures precision in every image.

Streamline Inspections, Organize Data, and Manage Condition Monitoring Activites Across Maintenance Teams

FLIR Thermal Studio Suite

Whether you're working with a handheld thermal imaging camera, acoustic imaging camera, or optical gas imaging (OGI) camera, the best solution for organizing and managing inspection programs for the Mining industry is FLIR Thermal Studio Suite. This subscription software offers the organizational features and advanced processing needed for predictive maintenance on critical components, system troubleshooting, and increased productivity.

FLIR Thermal Studio Pro is a desktop software offering batch image processing, advanced image analysis, and access to FLIR Route Creator: a feature that lets users create their own inspection map and download it to a FLIR camera with Inspection Route enabled.

FLIR Ignite

When paired with the FLIR IgniteTM cloud service for direct image back up, FLIR Thermal Studio software ensures accurate data collection that helps predictive maintenance crews spot problems before they cause critical failures.

FLIR Thermal Studio

FLIR Ignite

Condition Monitoring Solutions for Mining Applications

FLIR A500f/A700f Advanced Smart Sensor

Fixed-Mount Thermal Imaging Camera for Condition Monitoring and Early Fire Detection

View Product

FLIR Si2x-Pro™

FLIR Si2x-Pro Hazardous Location Acoustic Imaging Camera for Gas Leak, Mechanical Fault, and Partial Discharge Detection

View Product

FLIR Si2x-LD™

Hazardous Location Acoustic Imaging Camera for Pressurized Leak Detection and Mechanical Fault Detection

View Product

FLIR Si2-Pro™

Industrial Acoustic Imaging Camera for Partial Discharge Detection, Pressurized Leak Detection and Mechanical Fault Detection

View Product

FLIR Si2-LD™

Industrial Acoustic Imaging Camera for Pressurized Leak Detection and Mechanical Fault Detection

View Product

INNOVATION IN ACTION

FLIR Thermal Imaging Enables Autonomous Inspections of Mining and Trucking Vehicles in Australia

Read the story

FLIR enables real-time liquid leak detection in the mining industry

Read the Story