Can an Integrated MWIR Camera and Continuous Zoom Lens Save Time and Money?

Advantages of Developing MWIR Imaging Platforms with Designed-in Zoom Optics

Midwave infrared (MWIR) cameras and continuous zoom optics are the preferred solution for providing clear thermal image detail over a range of distances. MWIR systems are common in military, law enforcement, and other long-range surveillance applications.

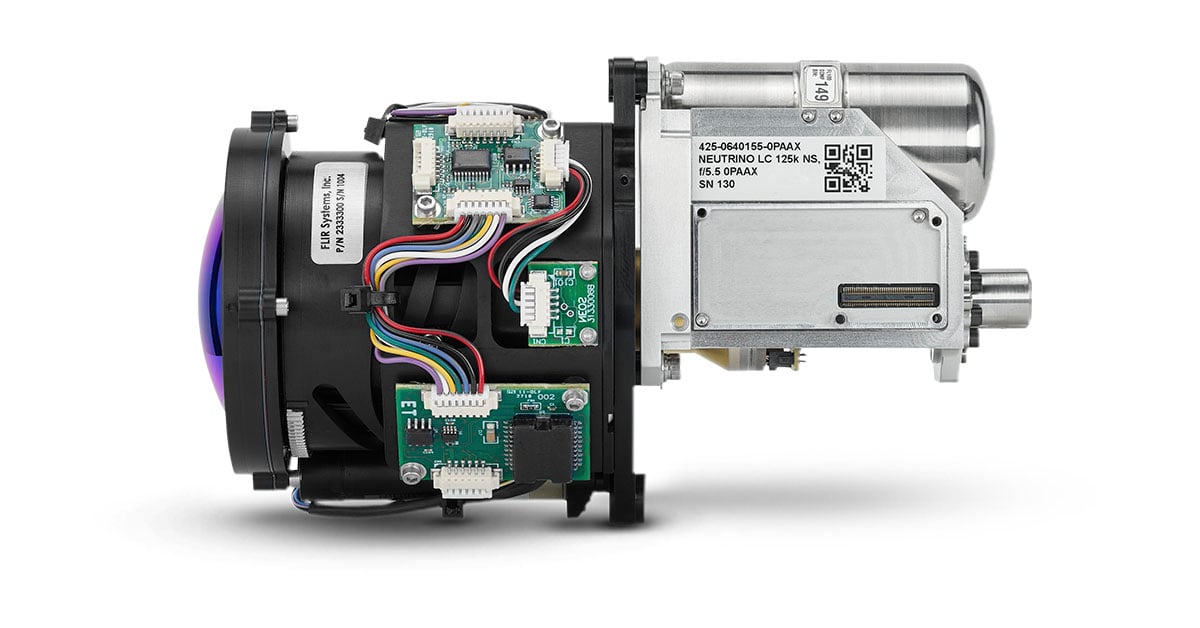

Recent advancements in high operating temperature (HOT) MWIR sensors have enabled size, weight and power (SWaP) reductions at the camera and system level. For example, the FLIR Neutrino LC HOT MWIR camera module volume is less than 210 cm3 (< 13 in3) and the cooling requirement is reduced by almost 50 percent.[i] [1] Its small size and faster time-to-image make the Neutrino LC suitable for drone use, as well as man-portable applications such as weapon sights and thermal binoculars.

Just as important as the thermal camera is the lens. In contrast to visible zoom lenses, MWIR continuous zoom (CZ) optics are much more complex and costly due to the exotic materials required and challenges to maintain focus over the entire zoom range – especially over a wide temperature range.

Traditionally, developers of MWIR imaging platforms must work with multiple partners to source the sensor assembly, optics, electrical, and packaging subsystem components. With FLIR Systems’ acquisition of New England Optical Systems (NEOS) in early 2019, FLIR’s Components OEM customers are now able to work with a single trustworthy company to provide their system, from design to integration to testing and deployment. This paper reviews the current challenges of MWIR imaging platforms and illustrates how FLIR, as a single solution provider, reduces time to market, performance risk and affordability while providing other tangible benefits.

CHALLENGE

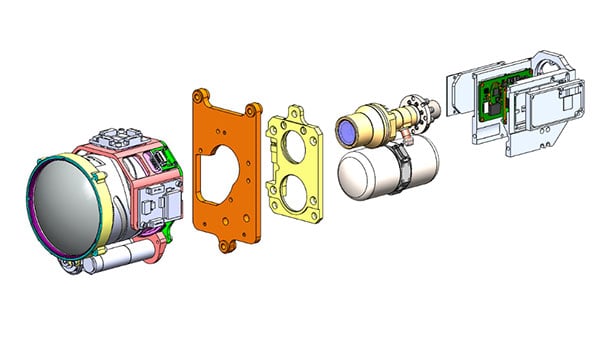

A MWIR imaging camera consists of multiple subsystems. The optics collect and focus the MWIR “light” onto the detector subassembly. The detector subsystem includes a focal plane array (FPA), readout integrated circuit (ROIC), and integrated detector/dewar/cooler assembly (IDCA).

Figure 1: Assembly of the FLIR Neutrino LC with the FLIR 19-290 Continuous Zoom Lens

Camera electronics process the information from the IDCA into usable data or an image. Development teams must consider many variables from multiple components such as pixel size, frame rate, field of view, image processing options, zoom range, aperture size, environmental conditions and much more.

The zoom optics subsystem provides the field of view or optical magnification to the camera. When determining which lens to use, integrators must consider such variables as nominal performance over temperature, mounting arrangement, focus shift over the zoom range, tolerance analysis, MTF, distortion, and thermal and range compensation.

Both camera and lens require electronics and software. Overall electronics packaging considerations include command and control, data interfaces, power, throughput, envelope, and environmental protection for these electronics.

On MWIR imaging platforms, development teams are challenged further by usually acquiring components for these subsystems from two or more different providers while attempting to maximize performance. Reduced system performance is likely when integrating “stand-alone” components. This can also lead to efficiency loss, needless complexity, more down time and overall lower reliability.

For example, a development team must account for the following considerations when integrating a thermal camera with a third-party optic:

- Separate procurement and engineering efforts are required.

- An integrator – possibly a third-party – is required to assemble, test, validate, and document the completed camera/lens system.

- Both camera and lens each require separate control and power interfaces, which can complicate development and system.

- While the camera and the lens (as separate components) may perform to specification, there may be compatibility issues. Considerable effort can be required to get the best matching performance at a system level over environmental conditions.

- When needing support or repairs, there are at least two separate entities to deal with. Depending on the complexity of the issue, it may not be obvious if the source of the problem is the camera, the lens, or the integration itself.

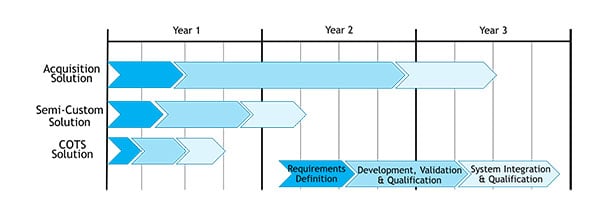

The project timeline to develop a MWIR imaging platform varies. If a new system requires an entirely new design such as an acquisition program (e.g. a project tender/RFP), two and a half years or longer is not uncommon. On the other end of the spectrum, if an integrated commercial off the shelf (COTS) solution is already available, the timeline can be measured in months. In between are semi-custom projects where small modifications can be made to existing cameras and zoom lenses in order to optimize specific critical parameters; these project timelines can be measured in quarters (Figure 2).

Figure 2. Notional project timeline – Integrated Thermal Camera and 3rd Party Optics

SOLUTION

FLIR is the only infrared camera manufacturer capable of providing MWIR camera solutions to meet these challenges head on - with its own zoom lenses designed for and fully integrated with its Neutrino™ portfolio of MWIR camera cores.

Designed-in Performance Benefits

FLIR’s cameras and lenses are designed for each other. Not as afterthoughts but optimized for SWaP, usability and image performance over a demanding environment.

The benefits start with tightly tolerancing the optics and camera to each other to minimize optics size and mass. This results in maximum performance out of the system. With a simplified and common electrical interface and software controls, a user has fewer connectors, cables and software SDKs to manage.

FLIR’s highly experienced manufacturing team precision align and integrate each camera and lens with a collimator and sophisticated test equipment – making sure each system meets requirements and will not change once in the field.

Time Benefit

FLIR is uniquely positioned as the industry’s only provider experienced in design, manufacturing and integration of the required subsystems for a complete solution. This includes IR detectors, cooling engines, zoom lenses, camera/lens electronics and packaging.

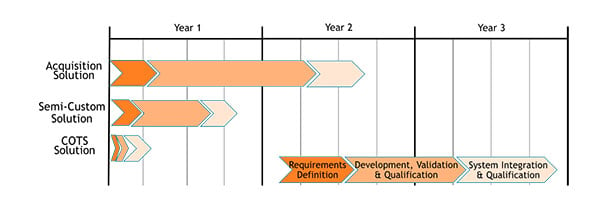

For these reasons, FLIR’s customers can greatly improve time to market (Figure 3). They now have access to a wide portfolio of commercial off the shelf (COTS) solutions ready for integration into their platforms (such as shown in Figure 4); these solutions are deliverable within weeks ARO. Semi-custom solutions can be acquired within nine months. For acquisition programs, developers can reduce time to market from thirty months to eighteen months by specifying requirements at higher assembly levels like those commonly available for commercial visible camera systems.

Figure 3. Improved project timeline -FLIR Camera and Integrated Optics

Working with a single vertically integrated solution provider will result in a shorter design cycle, streamlined procurement process and increased ability to create reliable solutions and provide a more rewarding experience to your customers.

Acquiring a system with an integrated MWIR camera and a continuous zoom thermal lens has never been this easy.

FLIR Reputation and Product Support

FLIR has been reliably providing MWIR camera cores for over twenty years. FLIR - Optical Systems Group (formerly NEOS) has over the last decade has become the recognized market leader for continuous zoom MWIR lenses. Together as a merged Line of Business (FLIR Industrial Technical Solutions – Components), we provide a powerful, reliable and compelling solution set for our customers.

FLIR has worked hard to ensure its products are synonymous with simplicity/ease-of-use, reliability, performance and behind the scenes support. FLIR’s comprehensive on-line product support is easily accessible and our highly qualified Technical Services team is dedicated to making our customers successful.

SUMMARY

Improvements in MWIR detectors and continuous zoom optics are converging to allow new and exciting SWaP optimized MWIR integrated solutions. There are design, time to market and other business challenges when attempting to procure and integrate these subassemblies independently.

FLIR has overcome these challenges by designing and integrating its own optics and cameras together. Now, as the only infrared camera manufacturer capable of providing MWIR camera solutions to meet these challenges, FLIR offers multiple and affordable ways to meet our customers’ MWIR solution requirements.

Click here to learn more about FLIR high performance IR optical assemblies.